Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

In the realm of electrical engineering, stainless steel’s durability and resistance to corrosion make it a material of choice for numerous applications. Its ability to withstand high temperatures and harsh environments ensures the longevity and reliability of electrical components.

Key Applications:

Conductive Components: Stainless steel is used to produce conductive elements that require both strength and resistance to oxidation.

Protective Enclosures: Electrical enclosures made from stainless steel safeguard sensitive equipment from environmental factors, ensuring operational integrity.

Transformers and Switchgear: Grades like Stainless Steel 310 are preferred for components exposed to high temperatures, such as in transformers and switchgear systems

These applications underscore stainless steel’s pivotal role in maintaining the safety and efficiency of electrical infrastructures.

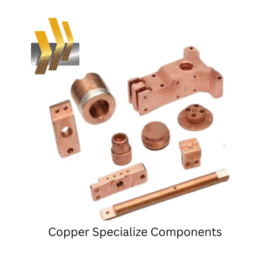

Copper is renowned for its exceptional electrical conductivity, second only to silver. This property ensures efficient energy transmission with minimal power loss. Additionally, copper's durability and resistance to corrosion make it ideal for electrical wiring and components, ensuring longevity and reliability in various applications.

Electrical-grade copper typically boasts a purity level of at least 99.95%. This high purity ensures optimal conductivity and performance in electrical systems. For specialized applications, such as in aerospace or semiconductor industries, copper purity can reach 99.99% or higher

Common copper types include:

• C110 (Electrolytic Tough Pitch - ETP): Known for its high conductivity and ductility, making it suitable for electrical applications.

• C145 (Tellurium Copper): Offers improved machinability while maintaining good electrical conductivity, ideal for precision components.

These variants cater to different mechanical requirements based on strength, machinability, and conductivity.

Copper's high thermal conductivity makes it excellent for heat dissipation. In mechanical applications, this property is beneficial for components like heat exchangers, radiators, and cooling systems, ensuring efficient thermal management.

Finishing processes enhance the appearance and performance of copper parts. Common techniques include:

• Polishing: Provides a smooth, shiny surface.

• Bead Blasting: Removes surface imperfections and prepares the surface for further treatment.

• Electropolishing: Improves corrosion resistance and surface finish.

These processes are crucial for applications where aesthetics and surface integrity are paramount

Yes, copper is 100% recyclable without any loss in performance. Recycling copper is energy-efficient and environmentally friendly, making it a sustainable choice for various industries.

Copper alloys exhibit a range of mechanical properties

• Strength: Alloying copper with elements like tin or zinc enhances its strength and hardness.

• Ductility: Copper alloys maintain good ductility, allowing them to be formed into complex shapes.

• Corrosion Resistance: Copper alloys resist corrosion, making them suitable for harsh environments.

Copper alloys are chosen for high-pressure applications due to their strength and ductility. In systems like hydraulics or deep-sea equipment, copper components withstand stress and deformation, ensuring reliable performance

Copper is used in various mechanical fittings, including:

• Valves and Pumps: Due to its corrosion resistance and machinability.

• Fasteners: Such as nuts and bolts, where conductivity and resistance to corrosion are essential.

• Heat Exchangers: Leveraging copper's thermal conductivity for efficient heat transfer.

When machining copper:

• Tool Selection: Use tools designed for soft metals to prevent smearing.

• Cooling: Adequate cooling is essential to dissipate heat and maintain dimensional accuracy.

• Alloy Choice: Selecting the appropriate copper alloy can improve machinability and meet specific mechanical requirements.

3 Stanhope Gate, Yorktown Business Park Camberley GU15 3DW. UK

© Copyright by Cytech Media