While brass remains a cornerstone in various industrial applications, the versatility and unique properties of aluminium have positioned it as a vital material across multiple sectors. At Kriloha Ltd., our expertise in brass components provides a solid foundation as we explore the expansive world of aluminium metal parts. This exploration underscores the significance of aluminium in electrical systems, die casting, mechanical fittings, and investment casting.

Aluminum’s excellent electrical conductivity, combined with its lightweight nature, makes it an ideal choice for various electrical applications. Its ability to dissipate heat efficiently ensures the longevity and reliability of electrical components. Key applications include:

Power transmission lines: Aluminum’s lightweight reduces structural support requirements.

Busbars and connectors: Efficiently conduct electricity with minimal energy loss.

Transformer windings: Benefit from aluminum’s thermal conductivity and cost-effectiveness.

The integration of aluminum in these components not only enhances performance but also contributes to energy efficiency and sustainability.

Die casting with aluminum allows for the production of complex shapes with high dimensional accuracy and smooth surface finishes. This process is favored for its ability to produce lightweight yet strong components, essential in industries such as:

Automotive: Engine blocks, transmission housings, and structural components benefit from aluminum’s strength-to-weight ratio.

Consumer electronics: Housings for devices like smartphones and laptops utilize aluminum for its aesthetic appeal and thermal properties.

Aerospace: Aircraft components require materials that offer durability without adding excessive weight.

Aluminum die casting not only streamlines manufacturing processes but also results in components that meet stringent industry standards.

In mechanical systems, the choice of material for fittings is crucial for ensuring durability and performance. Aluminum stands out due to its:

Corrosion resistance: Ideal for applications exposed to moisture or chemicals.

Lightweight: Reduces overall system weight, enhancing efficiency.

Malleability: Allows for the creation of intricate designs and custom fittings.

Common applications include:

Hydraulic and pneumatic systems: Aluminum fittings ensure leak-proof connections.

HVAC systems: Efficient airflow and temperature regulation rely on high-quality aluminum components.

Marine applications: Resistance to saltwater corrosion makes aluminum a preferred choice.

The adaptability of aluminum in mechanical fittings ensures reliability across diverse operational environments.

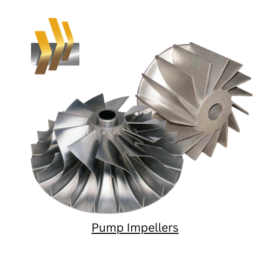

Investment casting, also known as lost-wax casting, is a process that allows for the creation of components with intricate geometries and excellent surface finishes. Aluminum’s properties make it particularly suitable for this method, offering benefits such as:

High dimensional accuracy: Reduces the need for additional machining.

Material efficiency: Minimizes waste, contributing to cost savings.

Versatility: Accommodates a wide range of complex designs.

Industries leveraging aluminum investment casting include:

Aerospace: Components like turbine blades and structural parts.

Medical devices: Precision instruments and implants.

Automotive: Engine components and performance parts.

The synergy between aluminum’s properties and investment casting techniques results in components that meet high-performance criteria.

Aluminium is renowned for its lightweight nature, corrosion resistance, excellent thermal and electrical conductivity, and malleability. These properties make it ideal for industries such as automotive, aerospace, construction, and electronics.

No, aluminium does not rust in the traditional sense. Instead, it forms a thin oxide layer when exposed to air, which protects it from further corrosion. This natural passivation makes aluminium highly resistant to environmental factors.

Aluminium parts are widely used in various sectors:

• Electrical industry: for conductors and heat sinks.

• Automotive and aerospace: for structural components due to its strength-to-weight ratio.

• Construction: for window frames and roofing.

• Consumer goods: such as cookware and packaging.

Aluminium has a melting point of approximately 660°C (1220°F). While it performs well in moderately high temperatures, it's essential to consider specific alloy compositions and treatments for applications involving sustained high heat.

Yes, aluminium is 100% recyclable without any loss in its inherent properties. Recycling aluminium requires only about 5% of the energy compared to producing primary aluminium, making it an environmentally friendly choice.

Aluminium alloys are categorized based on their composition and properties:

• 1000 series: Pure aluminium, excellent corrosion resistance.

• 2000 series: High strength, used in aerospace.

• 6000 series: Versatile, good strength and corrosion resistance, common in structural applications.

Aluminium is lighter than steel and copper, offering a better strength-to-weight ratio. While it may not match the strength of steel or the electrical conductivity of copper, its corrosion resistance and ease of fabrication make it a preferred choice in many applications.

Common surface treatments include:

• Anodizing: Enhances corrosion resistance and allows for coloring.

• Powder coating: Provides a durable and decorative finish.

• Polishing: Improves appearance and smoothness.

While aluminium offers many advantages, it has some limitations:

• Lower strength compared to some steels: May not be suitable for all structural applications.

• Thermal expansion: Higher than steel, which can affect dimensional stability.

• Welding challenges: Requires specialized techniques due to its thermal conductivity.

At Kriloha Ltd., we adhere to stringent quality control measures, including:

• Material certification: Ensuring the use of high-grade aluminium alloys.

• Precision manufacturing: Utilizing advanced machinery for accurate dimensions.

• Surface inspections: Checking for defects and ensuring proper finishes.

Our commitment to excellence guarantees that our aluminium parts meet the highest industry standards.

3 Stanhope Gate, Yorktown Business Park Camberley GU15 3DW. UK

© Copyright by Cytech Media